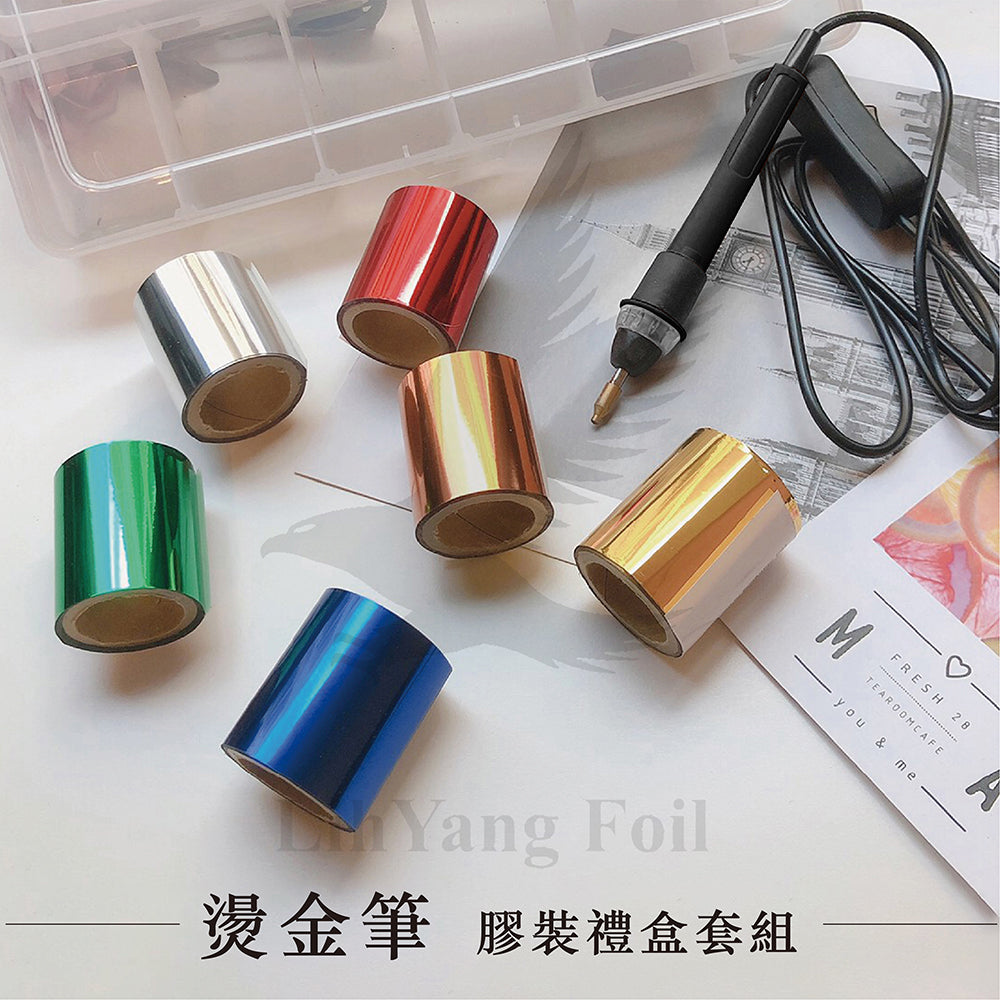

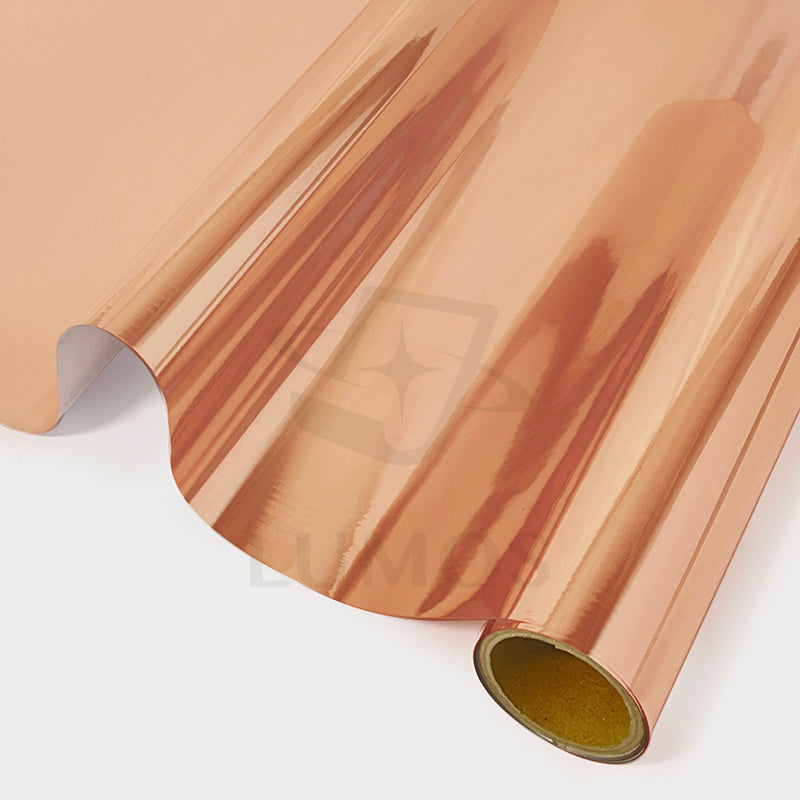

高光金屬系列 燙金箔│ 碳粉過護貝機、膠水筆 專用

Couldn't load pickup availability

Dimensions Specifications

Dimensions Specifications

Contact us for customized specifications

Materials

Materials

foil

Shipping & Returns

Shipping & Returns

Orders will be shipped within three days / pre-orders will be shipped within 14 days

Care Instructions

Care Instructions

Share

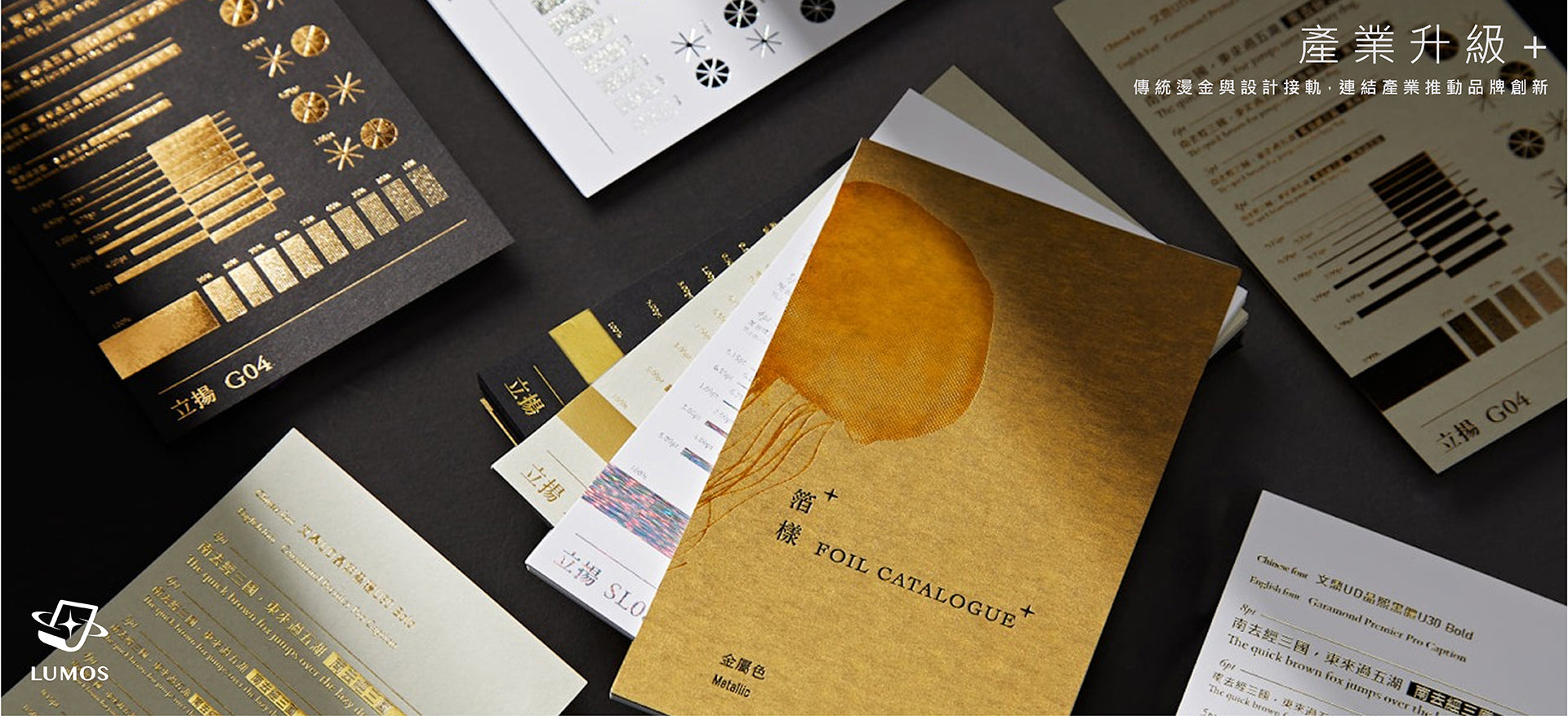

High Gloss Metal Toner Reactive Foil│for Toner/ Glue Pen 【LUMOS】

Not for Hot stamping pens.

◆Feature: Metal effect foil for package and handmade design; suitable for paper.

◆Specification: 10cm x 500 cm/roll

◆Color: High Gloss Gold / High Gloss Light Gold / High Gloss Solid gold/ High Gloss Gold Rose/ High Gloss Bronze/ High Gloss Amber gold

◆Equipment: Toner printed throuth laminator /Glue Pen

<Method 1 - Glue Pen Foil Stamping>

Write on paper wih glue pen, Kuretake ZIG Glue pen use by squeezed; the Rainbow Glue pen use by ballpoint.

Wait 10 minutes to the glue dry fully, then stick the foil on it. Push out the contour with a cotton swab carefully and softly, and quickly tear off the foil PET surface.

<Method 2 – Toner Reactive Hot Stamping>

♦ Paper suggestioin ⇨ Recommend use non-textured paper to avoid toner adsorbing uneven, such as matte coated paper.

♦ Principle ⇨ adhesive of toner foil will react with toner after heating, making the foil pigment adhere to the paper printed with toner printer. "Most" glue pens could be used for toner foil paper.

♦ Method ⇨

step 1. Print out the pattern (at least 1mm thickness) you want to stamp on the paper with "toner" printer. ※Remarks: Traditional inkjet printers cannot used for toner stamping.

step 2. Stick the toner foil on one side with "paper tape" before 110-160°C. pass it through the laminator. While laminator preheating, put the printing paper pasted with foil on the laminator to preheat, so that foil is more attached to the paper.

※Remarks: (1) The foil should be smaller than the printed paper card to avoid foil curling when passing through the laminator.

(2) Paper tape for fixxing can only be pasted on one side direction which will enter the laminator.

step 3. Try to put "thin paper" on the foil paper while passing through the laminator,

Order: thin paper> toner foil> printed paper card

※Remarks: The protective paper should not be too thick, otherwise it will cause insufficient temperature.

step 4. After hot pressing by laminator, do not completely tear off the foil paper and tape. If the hot stamping pattern is incomplete, may be due to insufficient temperature or uneven foil. Put the foil flat again or cut a small piece foil, then paste it on paper card with tape and pass through the laminator again to fill the foil pattern.

< Common Q&A >

♦ Paper suggestioin ⇨

Recommend use non-textured paper to avoid toner adsorbing uneven, such as matte coated paper.

♦ Pattern with black border ⇨ If the hot stamping pattern is incomplete, may be due to insufficient temperature or uneven foil. Put the foil flat again or cut a small piece foil, then paste it on paper card with tape and pass through the laminator again to fill the foil pattern.

♦ Residue foil or warping foil after through the laminator ⇨

Toner may residue on the dense pattern, will cause the foil to react and stick to the paper. Remove excess foil by paper tape or eraser.

⚠️Color difference may happen due to the screen photos. Please contact us to check colors.

⚠️Customized roll widths are available. Please contact us for MOQ.

Series classification

View all-

🔻 Toner Reactive Foil Paper ┃for Laminator

Hot stamping foil for lacer toner printing machine throuth laminator.